5G Engineering Co-op

I tested devices to make sure they are safe for the Verizon network during my co-op.

2024

Computer Networking

Fusion 360

Overview

I was a 5G Engineering co-op at Verizon! During my time there, I was on the device testing team, where we focused on testing devices such as smartphones or Wi-Fi routers to ensure performance and also to make sure they are safe for the Verizon network and won't cause overloads. In addition to my primary responsibilities in device testing, I gained valuable experience in managing the lab network, establishing redundancy across all the lab, and maintaining the lab 3D printer, overseeing operations and creating test fixtures. This experience allowed me to explore both device testing and lab management, deepening my understanding of the 5G technology landscape.

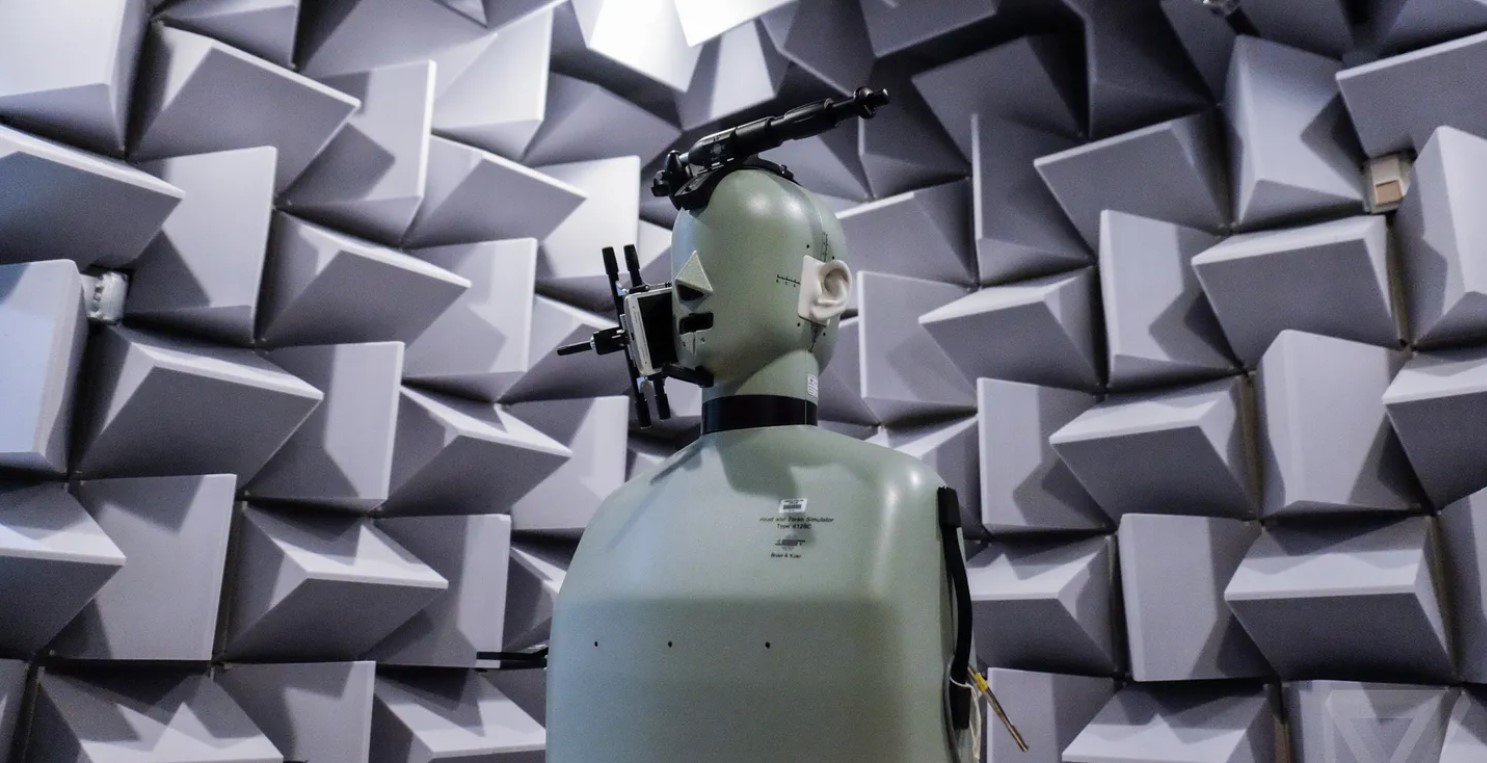

Device Testing

During my co-op at Verizon, I was actively involved in testing both the capabilities and performance of devices. I tested 7 flagship smartphones and fixed wireless routers running pre-commercial software, quickly gaining a deep understanding of the wireless industry’s concepts and terminology. Despite starting with limited knowledge, I successfully executed numerous tests and presented detailed analyses to management at the director level.

Working in an ISO, CTIA, and GCF certified lab, I became proficient in the testing protocols and standards. I utilized advanced testing platforms to assess device capabilities and radio frequency performance, uncovering 3 critical device failures before they could impact customers or the Verizon brand. Additionally, I collaborated with 3rd party vendors to provide feedback on testing software and conducted regular quality assurance on development platforms, which improved test accuracy and reduced test time by over 50%.

Working in an ISO, CTIA, and GCF certified lab, I became proficient in the testing protocols and standards. I utilized advanced testing platforms to assess device capabilities and radio frequency performance, uncovering 3 critical device failures before they could impact customers or the Verizon brand. Additionally, I collaborated with 3rd party vendors to provide feedback on testing software and conducted regular quality assurance on development platforms, which improved test accuracy and reduced test time by over 50%.

Networking

In any organization, the network infrastructure is a crucial but often overlooked component that ensures everything functions smoothly. During my time at Verizon, I gained valuable experience in maintaining the lab network used daily by over 70 employees.

A major project I undertook was building a redundant lab network to enhance reliability. Initially, the lab network lacked redundancy, meaning a failure in one of the core switches could disrupt internet access for around 90% of the lab's shield rooms. I reconfigured over 200 switches to establish a redundant network, ensuring continuous connectivity. This project required me to trace and document all network cables, as there was no existing documentation. I also created comprehensive documentation for future maintenance and upgrades, laying the groundwork for improved network management.

A major project I undertook was building a redundant lab network to enhance reliability. Initially, the lab network lacked redundancy, meaning a failure in one of the core switches could disrupt internet access for around 90% of the lab's shield rooms. I reconfigured over 200 switches to establish a redundant network, ensuring continuous connectivity. This project required me to trace and document all network cables, as there was no existing documentation. I also created comprehensive documentation for future maintenance and upgrades, laying the groundwork for improved network management.

3D Printing

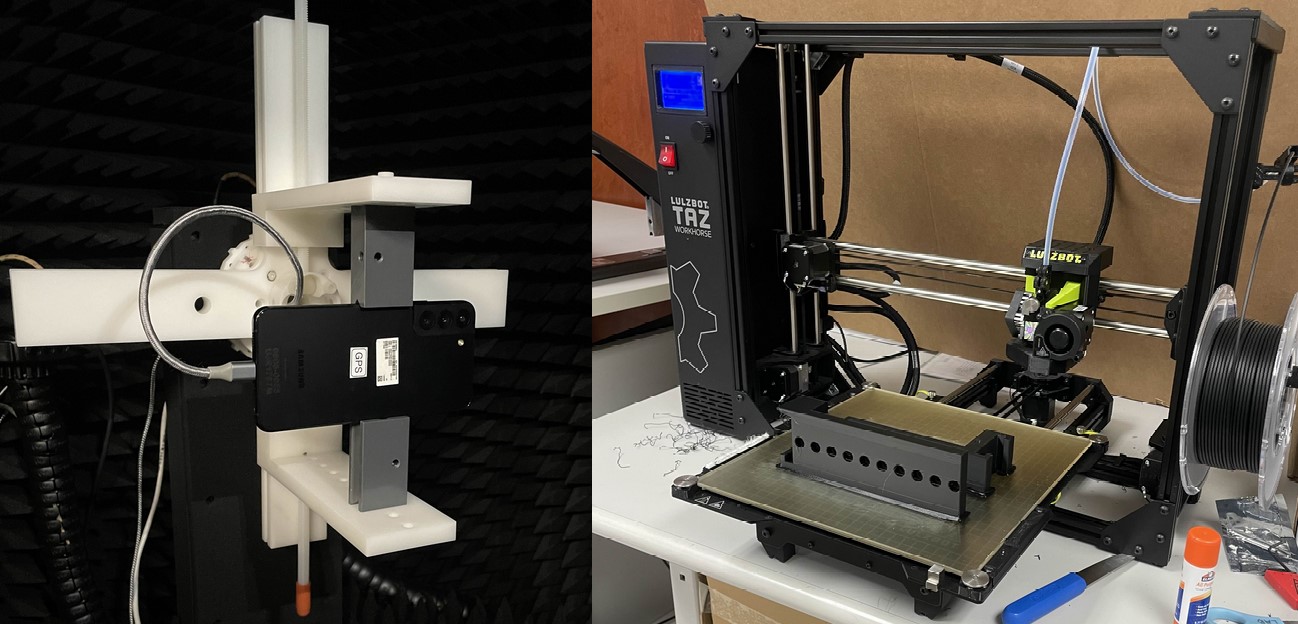

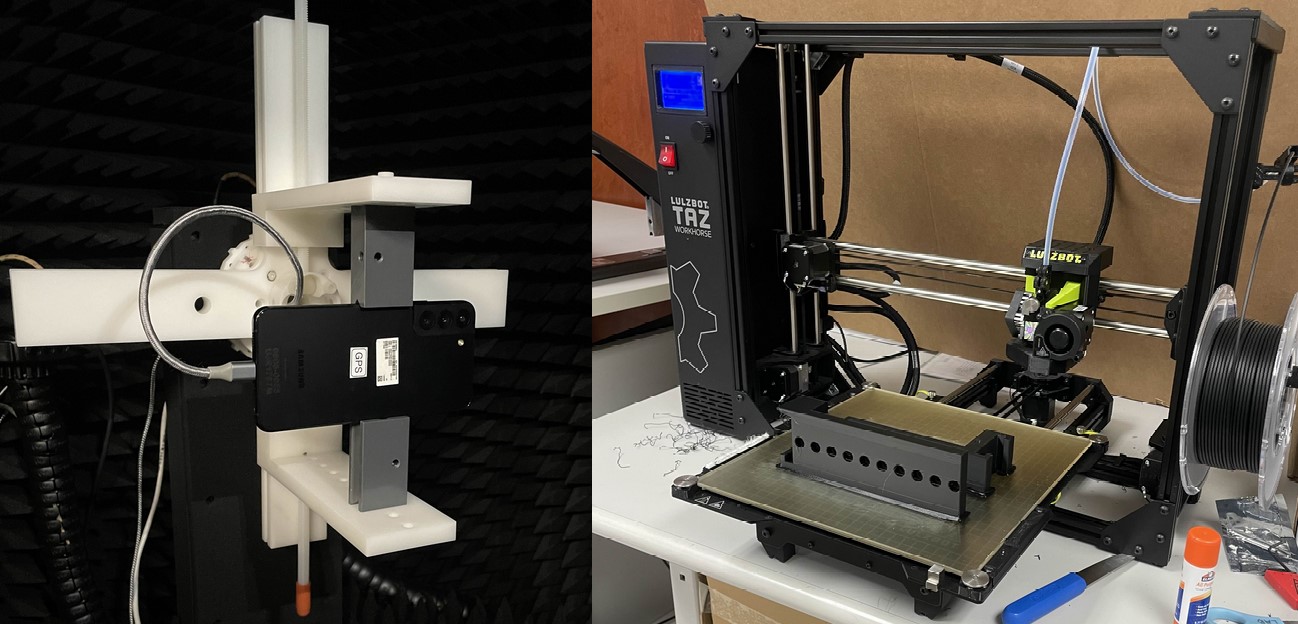

When I started my co-op at Verizon, I eagerly took on the challenge of revitalizing a long-unused 3D printer in the lab. I began by creating test fixtures that addressed specific lab needs and enhanced our testing capabilities.

One significant project involved designing and 3D printing new holders for radiofrequency performance testing of smartphones. The original holders caused interference and skewed test results due to their design, which obstructed the phone's antennae. I developed new holders with a 20% infill to minimize material interference and designed them to be adjustable for various phone sizes. This solution allowed the lab to create its own test fixtures in-house, saving money and increasing flexibility compared to relying on third-party sources. The new holders were tested against the old ones and demonstrated superior performance, leading to their adoption for future tests. In addition to this main project, I took on various side projects to support the lab’s operations. I designed and created phone holders that mounted devices against the wall, improving accessibility for testers and boosting productivity. I also crafted a Verizon-themed bagel cutter which boosted team morale :)

In addition to this main project, I took on various side projects to support the lab’s operations. I designed and created phone holders that mounted devices against the wall, improving accessibility for testers and boosting productivity. I also crafted a Verizon-themed bagel cutter which boosted team morale :)

One significant project involved designing and 3D printing new holders for radiofrequency performance testing of smartphones. The original holders caused interference and skewed test results due to their design, which obstructed the phone's antennae. I developed new holders with a 20% infill to minimize material interference and designed them to be adjustable for various phone sizes. This solution allowed the lab to create its own test fixtures in-house, saving money and increasing flexibility compared to relying on third-party sources. The new holders were tested against the old ones and demonstrated superior performance, leading to their adoption for future tests.

In addition to this main project, I took on various side projects to support the lab’s operations. I designed and created phone holders that mounted devices against the wall, improving accessibility for testers and boosting productivity. I also crafted a Verizon-themed bagel cutter which boosted team morale :)

In addition to this main project, I took on various side projects to support the lab’s operations. I designed and created phone holders that mounted devices against the wall, improving accessibility for testers and boosting productivity. I also crafted a Verizon-themed bagel cutter which boosted team morale :)