3D Printing

I model and 3D print things for fun!

2023 - Present

SolidWorks

Overview

For my birthday, I received a

Voxelab Proxima 6 SLA resin printer

after being quite interested in 3D printing for a while. Seeing my printer, my boyfriend also got really interested in the prospect of being able to 3D print, so he purchased aVoxelab Aquila S2 FDM printer.

In my free time, I like to model up various things to print from both our printers.Chair Leg Tip

As I heard my mom complaining about how the 5th chair leg tip she's tried was falling off or breaking, I was eager to try to help her situation with my new 3D printer. This was my first project with my 3D printer, and from it I learned a

This was my first project with my 3D printer, and from it I learned a

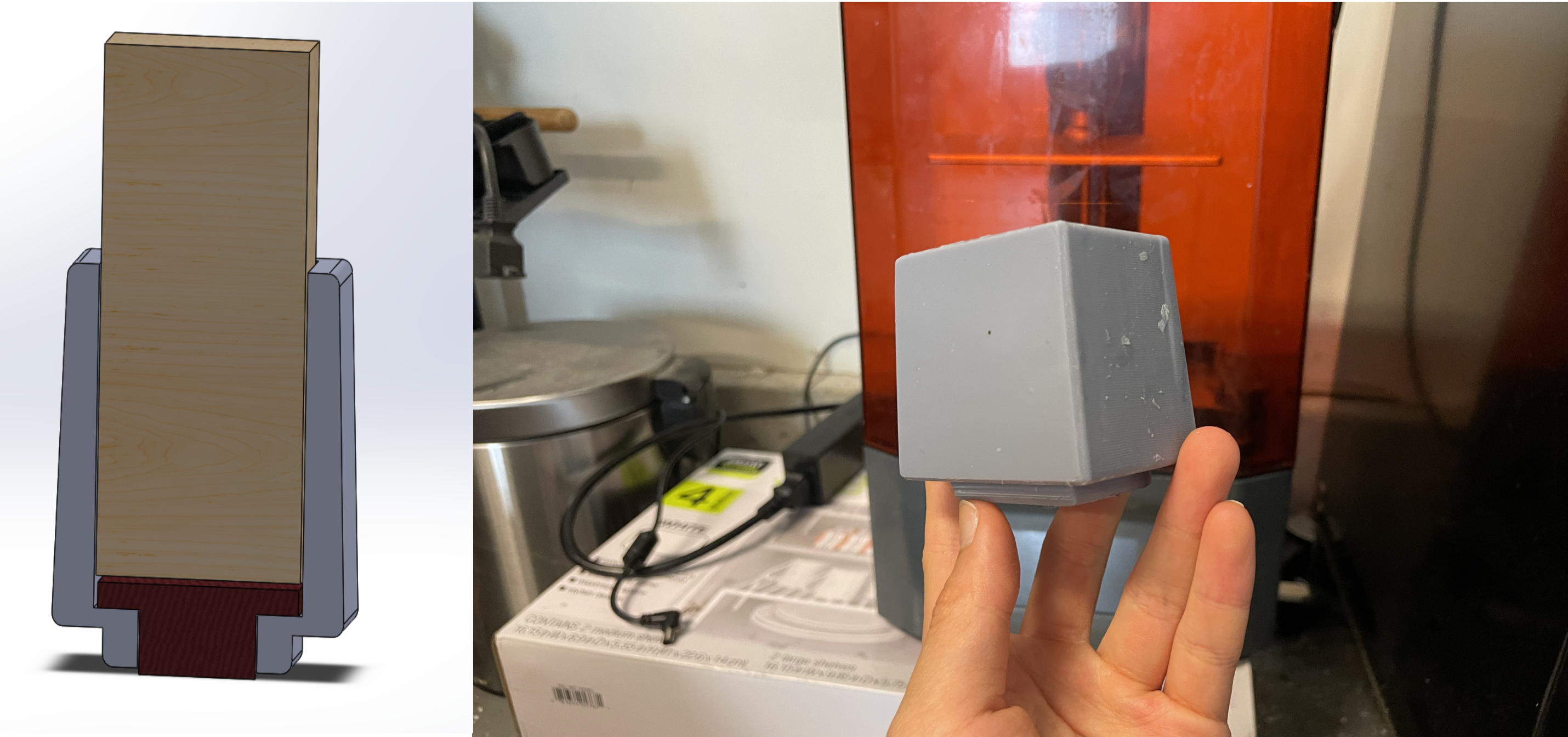

I first took measurements off of our house chair feet, and then designed a couple ideas I had. From there, came modelling and prototyping. I noticed that the problem with a lot of these leg tips was that it was either made from a rubbery plastic material that kept tearing, or the felt tip on the bottom that makes the chair glide on the floor would fall off. I came up with a design that fits snug around the leg and is also decently thick, to prevent breakage. It also includes a hole at the bottom where a felt piece can stick through, but be held in place by the chair and not be at risk of falling out. In the picture below is a cross section of this prototype. The gray is the leg tip, the brown is the chair, and the red is the felt piece.

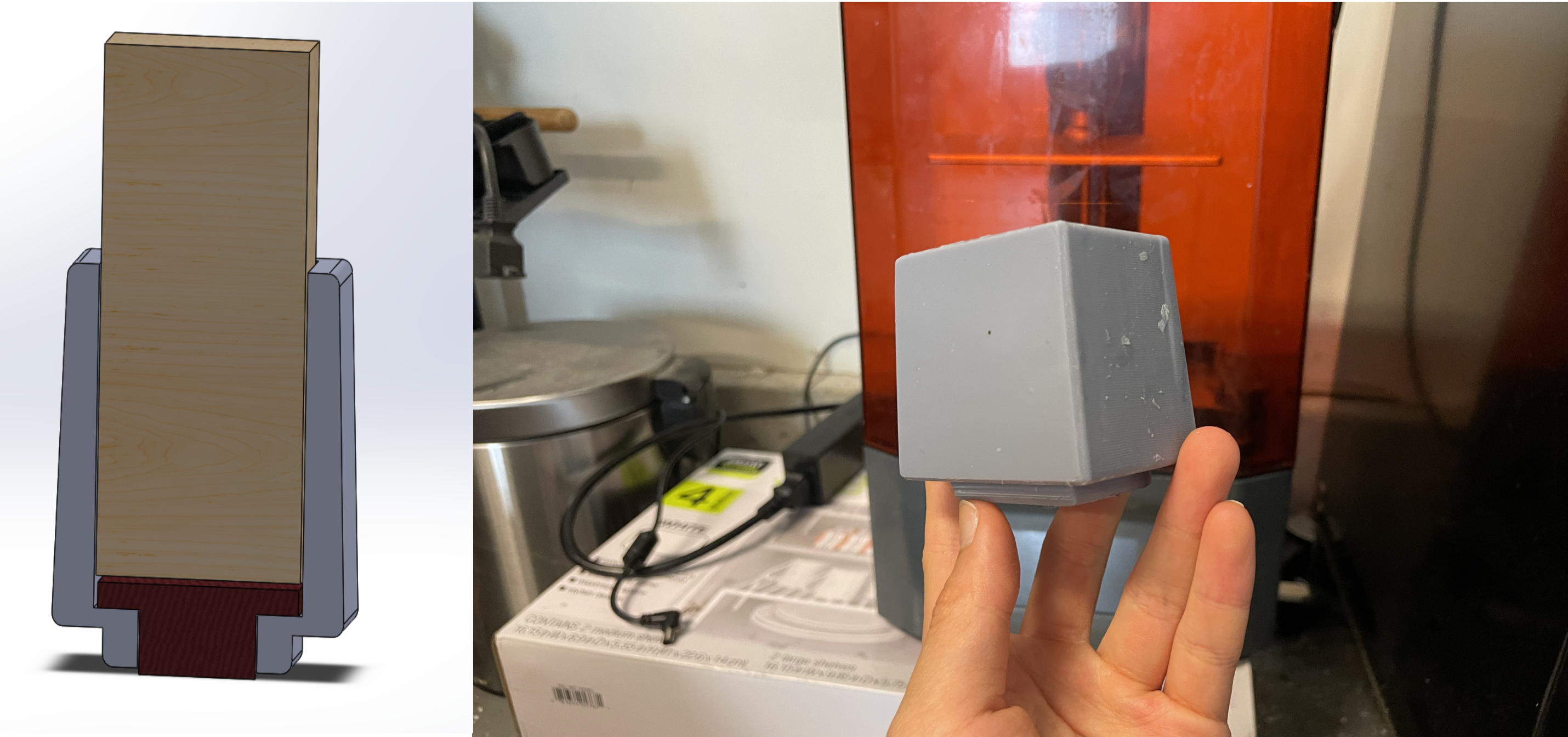

I learned very quickly the trials and tribulations that come with resin printing, getting resin all over the table, my tools, inhaling probably too much IPA fumes, and not even getting a successful print at the end. Through time, I learned

At the end, I was able to mock up and print a set of chair leg tips that my mom was very happy about:

This was my first project with my 3D printer, and from it I learned a

This was my first project with my 3D printer, and from it I learned a lot.

I first took measurements off of our house chair feet, and then designed a couple ideas I had. From there, came modelling and prototyping. I noticed that the problem with a lot of these leg tips was that it was either made from a rubbery plastic material that kept tearing, or the felt tip on the bottom that makes the chair glide on the floor would fall off. I came up with a design that fits snug around the leg and is also decently thick, to prevent breakage. It also includes a hole at the bottom where a felt piece can stick through, but be held in place by the chair and not be at risk of falling out. In the picture below is a cross section of this prototype. The gray is the leg tip, the brown is the chair, and the red is the felt piece.

I learned very quickly the trials and tribulations that come with resin printing, getting resin all over the table, my tools, inhaling probably too much IPA fumes, and not even getting a successful print at the end. Through time, I learned

the process of resin SLA printing, the possibilities, limitations, and requirements for a successful print.

At the end, I was able to mock up and print a set of chair leg tips that my mom was very happy about:

Nintendo Switch Cartridge Holder

Being an avid Nintendo Switch player, I have many games for the console. This means that the cases for the games tend to pile up and create a lot of clutter. To fix this, I wanted to model up a holder for just the cartridges themselves without needing the whole case. The goal going into this project was to create a strong, sleek looking case that could also hold a decent amount of game cartridges. I decided I wanted to model this case off of a Pokédex, a device from the video game Pokémon, as an extra challenge.

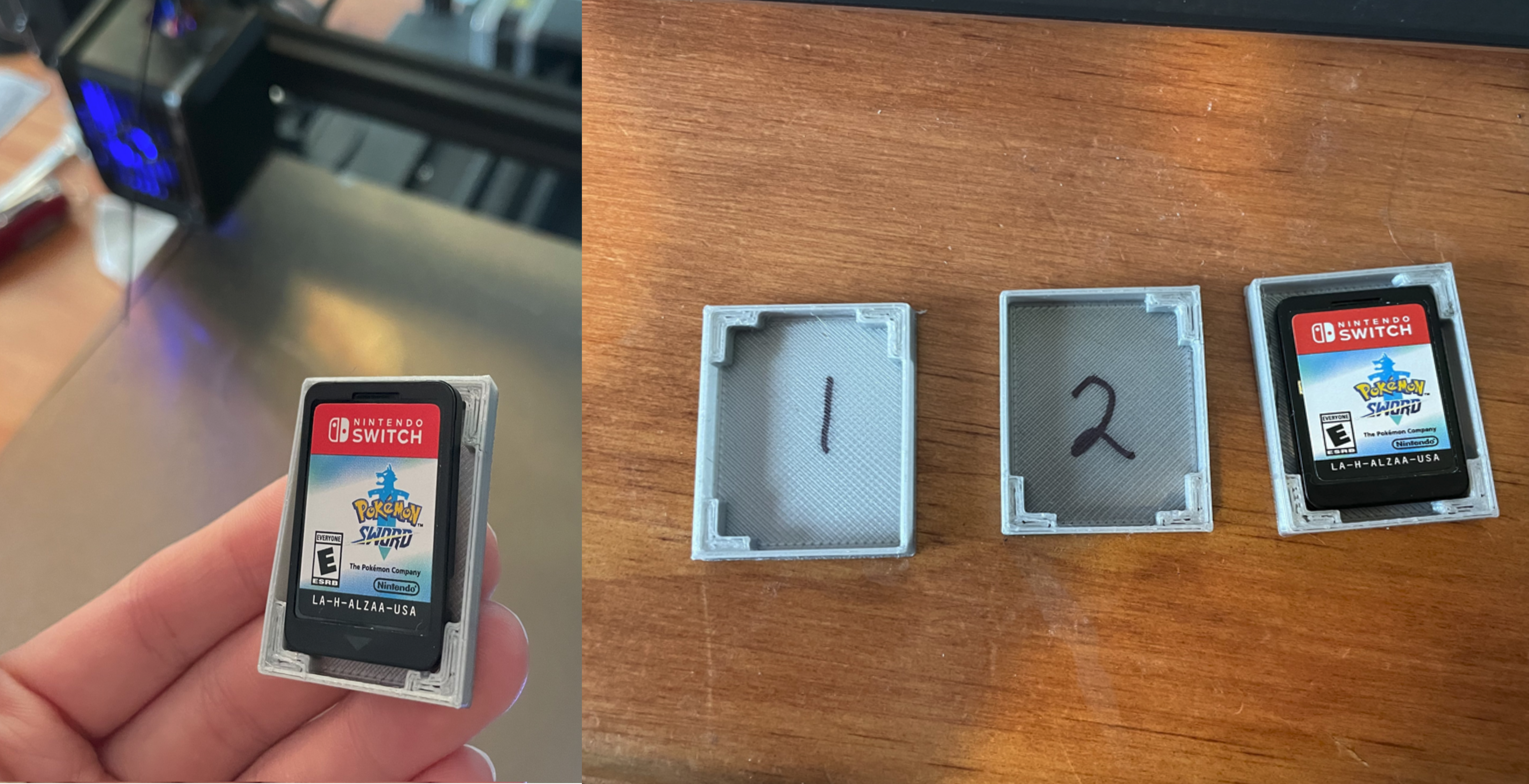

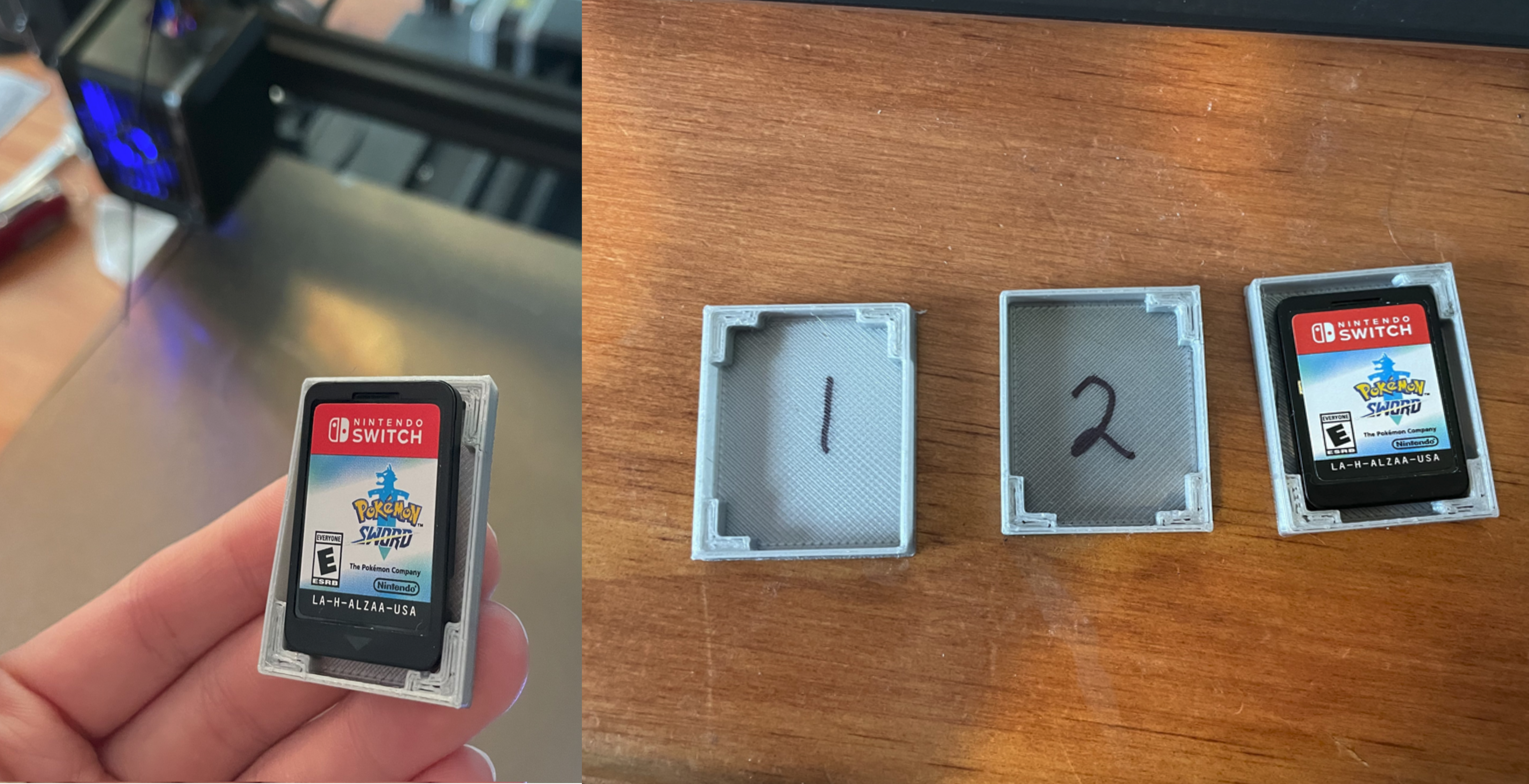

Going into designing the entire holder, I first needed to find the right dimensions for each cartridge slot so that it is big enough to fit the cartridge in, but also small enough to have a snug fit. I modelled various dimensions for the slot for printing to test them out. Once finding the right dimensions, I was able to model up the entire Pokédex itself, which consisted of 2 pieces that are built into each other. Each side could hold 9 Switch games for a total storage of 18 games. I made the two pieces to be built into each other by generating an assembly in SolidWorks and preassembling the two pieces together and then creating a gap of 1mm between the two pieces so that when it prints, it will print the two pieces to already be fitted into each other.

Once finding the right dimensions, I was able to model up the entire Pokédex itself, which consisted of 2 pieces that are built into each other. Each side could hold 9 Switch games for a total storage of 18 games. I made the two pieces to be built into each other by generating an assembly in SolidWorks and preassembling the two pieces together and then creating a gap of 1mm between the two pieces so that when it prints, it will print the two pieces to already be fitted into each other.

This endeavor presented a valuable opportunity for me to

Going into designing the entire holder, I first needed to find the right dimensions for each cartridge slot so that it is big enough to fit the cartridge in, but also small enough to have a snug fit. I modelled various dimensions for the slot for printing to test them out.

Once finding the right dimensions, I was able to model up the entire Pokédex itself, which consisted of 2 pieces that are built into each other. Each side could hold 9 Switch games for a total storage of 18 games. I made the two pieces to be built into each other by generating an assembly in SolidWorks and preassembling the two pieces together and then creating a gap of 1mm between the two pieces so that when it prints, it will print the two pieces to already be fitted into each other.

Once finding the right dimensions, I was able to model up the entire Pokédex itself, which consisted of 2 pieces that are built into each other. Each side could hold 9 Switch games for a total storage of 18 games. I made the two pieces to be built into each other by generating an assembly in SolidWorks and preassembling the two pieces together and then creating a gap of 1mm between the two pieces so that when it prints, it will print the two pieces to already be fitted into each other.This endeavor presented a valuable opportunity for me to

challenge my SolidWorks skills while also showcasing my capability to prototype a functional solution.